The Problem Statement:

India’s leading Automotive manufacturer wanted to establish a robust system for inspecting gears. Gears are a critical component for transmitting power and motion, so it was very important for the automotive manufacturer to inspect gears as per the Engineering requirement.

Surface defects on gears like patches, scratches, horizontal lines, and dimensional deviations resulted in increased acoustic noise and affected Engine and Gear train performance. Defects detected manually were highly prone to subjectivity and were not a satisfactory method of quality control. Besides being subjective, it was also a time-consuming process.

The effectiveness of manual inspection decreased as workers doing the tedious, repetitive job got fatigued, working in varying light conditions in a harsh industrial environment. Operators often passed defective gears as ‘OK’, which were issued to the Production line where the defective gear could not be identified until the gearbox was fully tested.

The Automotive manufacturer had to then engage additional resources to disassemble the faulty gearbox and send it for rework, which took time and was expensive and an inefficient process. It was, therefore, important for the automotive maker to come up with a reliable and consistent method for detecting defects and dimensional deviations on gears which eliminated subjectivity.

The Solution:

The Automotive manufacturer deployed OPTIVITY® Gear Inspection, an intelligent AI vision-based Gear inspection system from Griffyn Robotech, which rapidly checked the complex geometry and defects on gears with ease and precision. The system leveraged an advanced image processing deep learning algorithm, which processed all captured parameters (data) of the gear, identifying geometrical deviations and defects with 100% accuracy helping the Automotive manufacturer to assemble gears with zero defects and 100 % quality assurance.

How did the OPTIVITY® Gear Inspection System Work?

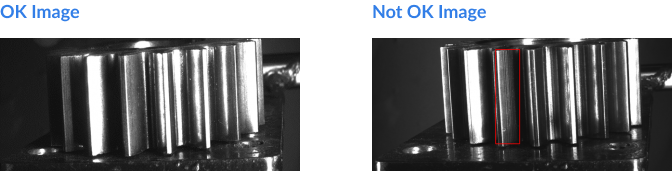

A reference model was made in which the OPTIVITY® Gear inspection system was trained with input images where images were classified into OK (parts without defects like cracks, patches, horizontal lines and the required number of teeth and specified inner and outer diameter) and not OK (parts with defects like cracks, horizontal lines, and patches along with dimensional deviations which were not acceptable).

Based on these images, the deep learning algorithm of the OPTIVITY® Gear Inspection system learned the acceptable form of Gear quality in varying light conditions. The OPTIVITY® Gear Inspection system equipped with a camera with efficient image illumination, captured images of the gears, which were then extracted and compared with the reference model, which enabled the system to notify images of gears that fell outside the acceptable range of quality, helping the automotive maker to inspect gears reliably and consistently.

Benefits to Customer:

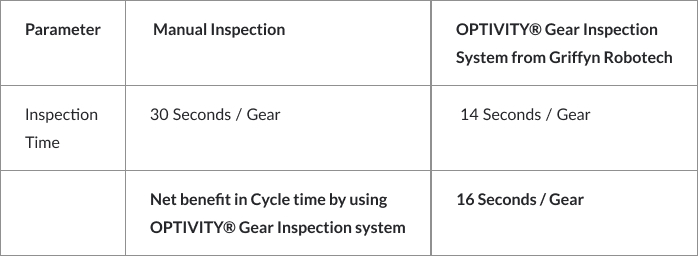

With OPTIVITY® Gear Inspection system, the automotive maker established a robust system of inspecting gears which resulted in a reduction of the Inspection cycle by approx. 54%.

The advanced vision inspection system available in OPTIVITY®’s Gear Inspection system monitored all gear parameters and identified deviations. It prevented defective gears from being used in the assembly, resulting in improved efficiency and quality control.

Manual inspection, which was prone to errors, was being performed in 30 seconds for one gear. OPTIVITY® Gear Inspection System provided by Griffyn Robotech could do the same operation in 14 seconds with 100% accuracy.

Conclusion:

Vision technology with AI will increasingly be adopted by manufacturers to improve productivity, product quality, and operator safety. With detailed specific industry knowledge, we at Griffyn Robotech have introduced the intelligent inspection solution-OPTIVITY®, which provides complete inspection coverage for large and small components with ease and precision. At Griffyn Robotech, we provide the necessary customization & fully automated, high-speed vision inspection systems using leading-edge technologies like Robotics, machine vision, and AI.

Connect with us today to know how vision inspection technology can help your manufacturing facility be Industry 4.0 ready.

For more information, mail to contact@phoenix.tech